Data Loggers Providing Insight Into Actual Field Conditions

"What have my munitions been exposed to?” -- often during life extension efforts, safety assessments, or accident investigations, this is the first question asked. Yet there is typically only very limited information available to build the answer. This ignorance forces caution and conservative assumptions with respect to ageing conditions to limit user risk. There are many examples where this has led to the destruction of products that could have been used for a few more years in a safe and efficient manner.

Even though National authorities spend millions qualifying and purchasing munitions systems, very little is often spent on tracking the real environment these items are exposed to during their service life. Recently MSIAC set out to determine how this situation was changing, and help identify some of the efforts going on among our member nations to deploy and evaluate data logging technology. We also wanted to see how useful the collected data might be, and how member nations might be using that information to change their procedures.

MSIAC has compiled a comprehensive limited report (L-193) summarizing:

- the results of a survey sent to representatives in its member nations,

- documents from the NATO science and technology exchange groups dealing with this topic, and

- other literature found in its database and other sources.

The report illustrates environmental data logger use, and how the data collected by loggers is being used. The types of sensors and their physical and technical characteristics are presented, and examples are provided showing where and on which munitions they have been deployed.

In various cases, different geographic deployment examples are provided, as well as different types of installations on the munition items themselves.

The examples also show how the logger systems provide access to the real environment the munitions are exposed to, and the effect of that environment on some select energetic systems. Some examples are also provided of data optimization methods to make data more useful in surveillance programs, life-extension decisions, detection of “out-of-specification” environments, combination with aging models to determine the current condition, and accident analysis. Moreover, data collected in some of these programs has allowed better understanding of the ammunition storage and deployment conditions in recent military operations such as Afghanistan and Iraq, as well as counter-piracy operations in the Gulf of Aden and in the Mediterranean Sea.

Some highlights of the report include:

Previous NATO Activities

The NATO Science and Technology Organization Applied Vehicle Technology Panel (STO/AVT) has had a series of efforts in the area of health monitoring and management of munitions. Significant information on the use of data loggers as well as research and demonstrator programs has been collected from the following STO/AVT activities:

- AVT-119: Health Monitoring of Munitions (2003–2007)

- AVT-160: Health Management of Munitions (2007-2009)

- AVT-176: Advances in Service Life Determination and Health Monitoring of Munitions (2010)

- AVT-208: Technical advances and Changes in Tactical Missile Propulsion for Air, Sea and Land Application (2012)

- AVT-228: Lecture series on Munitions Health Management (2013)

- AVT-212: Application of Integrated Munition Health Management – Developing Methodologies for Implementation (2011– 2015)

The reports from these activities may be downloaded from NATO STO/AVT. Additionally, the report from the AVT-212 cooperative demonstration of technologies will be accessible on the MSIAC secure website under the reference L-192.

Questionnaire

A questionnaire was sent to the MSIAC member nations to get an overview of their involvement in this technology area. Australia, Belgium, Canada, Finland, Germany, Norway, Sweden and the UK provided direct responses to the inquiry, and The Netherlands asked MSIAC to refer to its published papers in this area as a basis for their work.

Environmental Data Loggers

Environmental data logger (EDL) is the title given to any device that will provide data about the environment surrounding it. The term is mostly associated with independent electronic devices that record and store temperature and humidity data, however, it should be taken as a more generic term covering all devices that improve knowledge of the environments experienced by an item. This can range from simple chemical devices that change colour at certain temperatures, to health and usage monitoring systems (HUMS) that can record temperature, humidity, shock, vibration, and pressure over many years.

As EDL technology advances, it should be incorporated into complementary in-service surveillance plans. The more that is known about the environment actually experienced by items in service, the more testing can be focused into areas of concern. A fully monitored fleet of missiles or munitions would allow fleet leaders, those that have seen the worst conditions, to be easily identified and tested. An example provided by users in the report is that flight hours were much higher than expected in Afghanistan and Libya engagements, which could help better define technical requirements in future acquisitions.

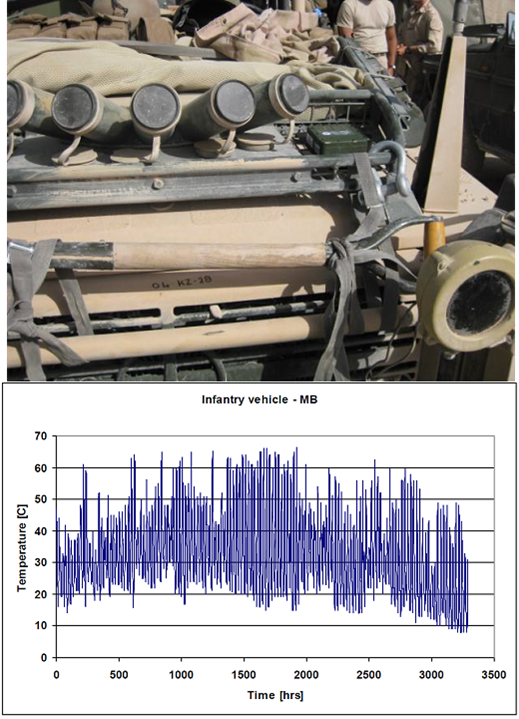

Figure 1: EDL next to a 66mm smoke launcher and corresponding data (courtesy of TNO).

NATO Policy

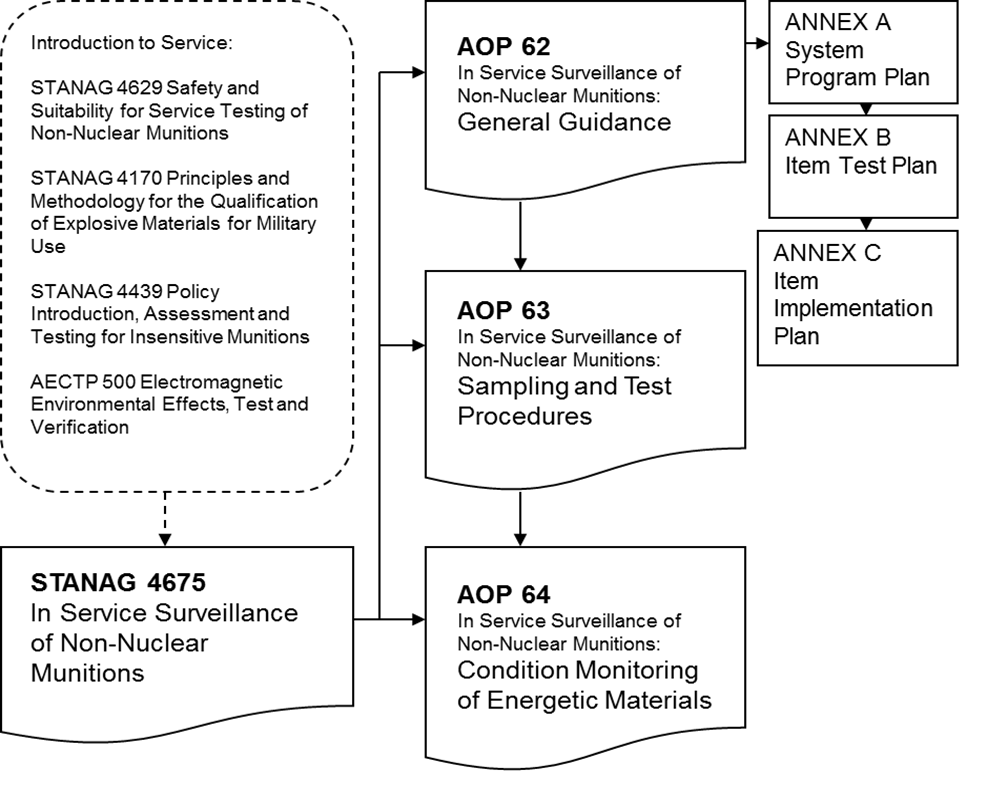

The use of data loggers for health monitoring or health management of munitions is linked with in-service surveillance activities and life assessment. NATO has recently drafted STANAG 4675 dealing with in-service surveillance of ammunition.

This STANAG covers:

- Methods of test and assessment

- Selection of surveillance assets

- Methods for determining life

It assumes that safety is the primary criterion for limiting a munitions’ life. Ratifying nations agree to follow the guidance given in the three AOPs and provide on-demand the relevant safety and reliability data indicated in them when transferring munitions to other NATO nations. STANAG 4675 has the following structure:

Figure 2: STANAG 4675 document structure

Munition Health Management

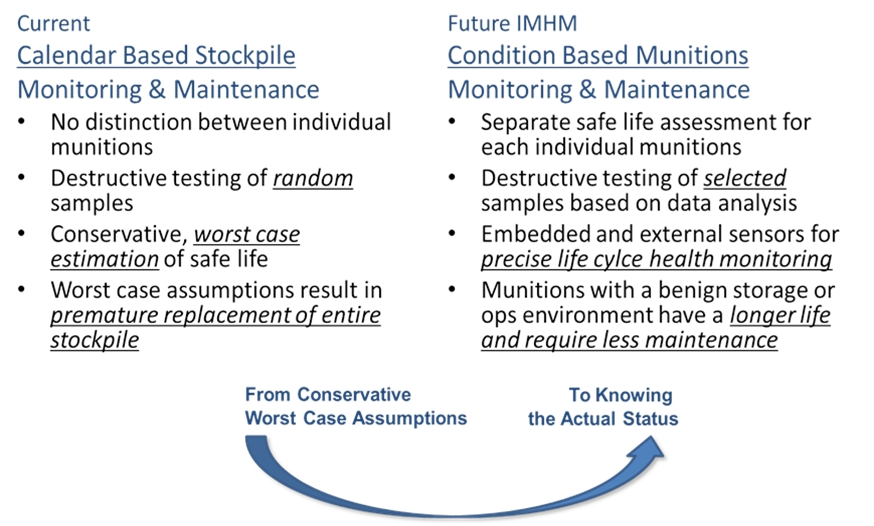

The idea of health management is to increase reliability and confidence in in-service surveillance decisions to better manage the stockpile, e.g.:

- to avoid disposing of munitions that are still reliable and safe,

- to avoid keeping in service munitions that are no longer reliable and/or safe,

- to adjust surveillance testing and inspection of munitions as a function of what they have actually experienced.

This could help save costs by reducing the number of destructive tests during surveillance and by extending the life of weapon systems. A potential additional feature includes tracking of munitions, which could be useful in order to track the stockpile and to get access to the main principles of MHM: condition, safe remaining life, and location of assets. The overarching goal would be a move to condition-based maintenance, where items that need attention get it, and ones that are still safe and fit-for-purpose are kept in the fleet:

Figure 3: Calendar based maintenance vs. Condition based maintenance

Emmanuel Schultz

MSIAC Propulsion Specialist