Technical Meeting: Non-Destructive Testing of Munitions

NDT Technical Meeting Agenda

Updated 17 April 2024

| Time | Item | Location |

| 08:30 | Arrival & Administration & Introductions | Taksim Room |

| 08:35 | Review of Day’s Schedule | Taksim Room |

| 08:45 | Keynote Presentation – Mr. Dan Pudlak, US Army | Taksim Room |

| 09:15 | Questions / Open Discussion | |

| Breakout Sessions Begin | Taksim / Nyhavn / Festplassen | |

| 10:00 | Coffee Break | |

| 10:20 | Breakout Discussions Continue | Taksim / Nyhavn / Festplassen |

| 12:00 | Lunch Break | |

| 13:15 | Breakout Discussions Continue | Taksim / Nyhavn / Festplassen |

| 14:30 | Coffee Break | |

| 14:50 | Breakout Discussions Continue | Taksim / Nyhavn / Festplassen |

| 16:30 | Summary Session | Taksim |

| 17:30 | HARD STOP |

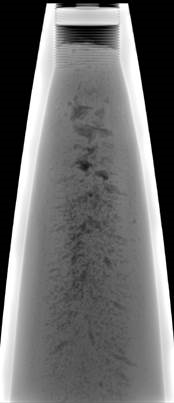

Figure 1: The Flow for the Discussion Groups in the NDT Technical Meeting.

Discussion Points

In preparation for the technical meeting, the participants are requested to review the questions and formulate initial responses prior to the meeting. The more informed the participant, the more every contributor will gain from attending the meeting.

The participant is requested to keep in mind that, consistent with the perspective of the three breakout groups, some questions may require detailed answers, others may not be that relevant.

Best Practices in the Detection of Defects

- Are there general rules or guidance available for technique development? This may be divided for different items: fuze, missile, shell, etc.

- What guidance is there for challenging situations, such as the two examples of O-rings in rocket motors and base gaps in artillery shells that were provided during the on-line plenary session in 2021?

- Are there general rules to guide computed tomography (CT) employment versus 2-dimensional X-ray imaging? In any discussion, there should be a recognition of the different manufacturing contexts of a relatively few high value items, (missiles) and a large number of lower value items (artillery shells).

- Are there general rules for the most economic use of CT imaging or how to establish priorities for work? In discussion, there should be a recognition of the nature of the information sought, for example, qualitative, binary (yes/no), quantitative, and the criticality of the information.

- Are there best practices available for this quantity of data, security, how it is stored, and how it is retrieved?

- Are there best practice guidelines for the protection of data, identification, and association of images to the original data? Outside of obvious legal or proprietary concerns, are there guidelines for separating the image from the originating data?

- Are there any general guidelines for determining / tracking the radiation exposure of an item in case of a long exposure or repeated exposures?

Limitations & Capability Gaps in NDT

- What techniques could be developed to provide different and useful information? A discussion of the information could be drawn across scale, for example, material, component, and system. Output could be coordinated investigations of different techniques.

- What capabilities does artificial intelligence / machine learning offer for the causes, detection, characterization, and acceptance of defects?

Standardisation of Acceptance Criteria

- What (numerical) acceptance criteria are in use internationally for accidental munition reactions caused by defects (e.g. the commonly quoted “one in a million”)?

- What are these criteria based on (e.g. requirements of national legislation)? Is standardisation achievable, or are acceptance criteria too dependent on e.g. national risk tolerability criteria, specific environmental conditions?

- How are national defect acceptance specifications developed for different types of munitions / energetic materials / manufacturing techniques / loading processes? For example, are they empirically determined; determined through physical models; based on the limitations of the production process; based on the limitations of inspection processes; etc.?

- Could comparison of these specifications and / or development processes between nations assist understanding of defect criticality?

The meeting will be held on 13 May 2024, in advance of the EMTWG conference in Oslo, Norway, on 13 May 2024. The venue will be the Clarion Hotel, The Hub. Travel and accommodation information can be found on the EMTWG website. Attire is business casual.

Delegates should be prepared to discuss these questions and expand on areas of common interest. Delegates are strongly encouraged to bring their notes and writing materials (pens, paper, etc). Rooms will be equipped with a white board and internet access. Two coffee breaks are provided, lunch is not provided.

The registration to the event is now being wait-listed as the venue is expected to be full for the plenary session. To place your name on the waiting list, please contact Dr Kevin Jaansalu directly.

Please note that the registration to EMTWG 2024 is independent of this technical meeting.

For further information please contact Dr Kevin Jaansalu:

T: +32 2 707 5636

E-mail: k.jaansalu@msiac.nato.int