MSIAC Science of Cook Off Workshop - EXECUTIVE SUMMARY

EXECUTIVE Summary

MSIAC hosted a five day workshop at the end of April 2016 to discuss the science and understanding of, to quote Blaine Asay, “a very complex series of events” that is cook off. The workshop was held at the Executive Management Center, located in the business-focused midtown area of Atlanta, Georgia.

Interest in the workshop was high; more than 90 people applied for the 75 available places at the workshop and the attendees came from ten of the thirteen MSIAC countries: Australia, Canada, Finland, France, Germany, the Netherlands, Norway, Sweden, the United Kingdom and the United States. Attendees represented government, industry and academia, and participated in an open forum for cook off discussions to take place between scientists from both the conventional and nuclear laboratories. People involved in testing, qualification and programme management were also present to provide balance to the deep technical discussions.

The workshop’s objectives were to improve the understanding of cook off of energetic materials and their systems. These objectives were achieved through discussions and presentations on chemical and physical changes, heating rate and heating conditions, critical ignition and growth conditions, reaction phenomenology, models and modelling, and sub-scale testing to system-level tests.

In reviewing the science of cook-off, the workshop participants would:

- Identify gaps in understanding

- Identify how we can apply our collective knowledge and tools (tests and models) to improve design and assessment of munition response to cook off today and in the future

- Understand the affect of heating rate (which may have future implications on full scale testing policy)

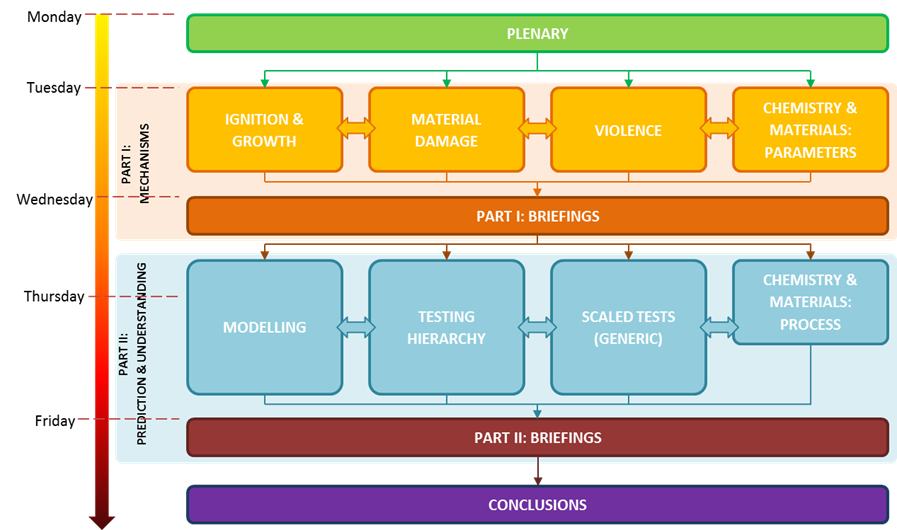

Figure 1 Workshop Structure

The workshop was spread over five days and opened with a plenary session designed to provide key discussion points for the remainder of the week. Participants were then split into two key areas: mechanisms and prediction & understanding (see Figure 1). To facilitate discussions, each key area was further sub-divided into four focus areas (see Figure 1), each led by a chair with support from an MSIAC staff member. Each focus area had specific goals and objectives that related to the main workshop goals.

Plenary Session

The session was opened by the MSIAC PM Dr Michael Sharp who welcomed the attendees to the meeting and provided a recap on the workshop’s objectives and how the output could influence a number of areas associated with cook off. Dr Matt Andrews then provided a welcome and administrative points for the week, followed by a brief history of cook off and thermal understanding from previous NIMIC and MSIAC workshops. It was highlighted that more than 13 years had elapsed since focused discussion had taken place in this area.

Dr Kerry Clark provided a review of work to understand the effect of heating rate and scale through FEA modelling. It highlighted that boundary conditions were as important as the size when determining ignition location. This was then followed by Albert Bouma and Dr David Hubble who provided an overview of the NATO Fast Cook Off (FCO) custodial working group work into understanding the complex problem of thermal flux within fuel and propane fires. At the opposite end of the heating range Dr Kevin Ford provided a summary of a recent JANNAF workshop on Slow Cook Off (SCO), which provided excellent points for discussion in a number of focus areas.

The technical presentations started with Dr Bryan Henson describing the thermal response of secondary explosives and providing insight into each stage of the process. This was followed by Dr Michael Hobbs highlighting the role of pressure during cook off of explosives through the use of bespoke instrumented test vessels. Dr Malcolm Cook then presented work on scaled tests used to understand violence of reaction and on advanced cook off experiments which enabled the visualisation of reaction progression.

Gert Scholtes provided an historical perspective to cook off work at TNO and within the community. Dr Libby Glascoe then discussed lab-scale cook off experiments used to explore mechanisms and develop high fidelity models. This led into the discussion by Dr Keo H. Springer on the current capabilities and future challenges of cook off modelling of explosives.

The final presentations then moved to discussing the hierarchy and applying this to the system level. The first of these was given by Alice Atwood who discussed the need to relate scaled tests to a working hierarchy process and challenged the participants to put their thinking caps on. The second presentation was given by Dr Fabien Chassagne who discussed the key factors and differences in reaction violence to thermal threats when testing solid rocket motors.

The plenary session was concluded with two National perspectives from the United Kingdom and Norway. Gunnar Nevstad provided an overview of Norwegian activities and Dr Phil Cheese highlighted the challenges in understanding and predicting aspects of cook off and provided motivation for the following days’ sessions.

Session Output

The subsequent three days provided time for some focussed discussions on all the areas of cook off. Below we have captured several key conclusions from each focus area; a more detailed review will be provided in the final report.

Ignition & Growth

The understanding of ignition location within an energetic material has become more complex than previous understanding; i.e. centre for slow heating and edge for fast heating. Experimental results showed that the physical state of a material greatly affects the ignition location, with molten materials being the most complex state to understand. It was observed that binder type influenced burning velocity and pressure but further work is needed to understand the mechanisms.

Experimental techniques exist to determine time to ignition and now this is complimented by new techniques to allow the visualisation of ignition and growth. Experimental techniques have also been developed to understand the effect of both pressure and temperature on burning rate of a range of energetic materials. This data is important as input parameters into models.

The understanding of thermally damaged material was identified as a gap and the need to develop tools to access this space was discussed. New models are also required to describe molten materials that are stable below the ignition temperature.

Material Damage

The current understanding of material damage, from individual components of formulations to the system, were captured. Mechanisms, material constraints, experimental techniques, and gaps were all covered.

The key outputs from the group highlighted the importance of both ullage and voids in affecting the rate of reaction. It was discussed that, within a thermally damaged material, many mechanisms exist for the formation of voids within a material and this in turn leads to increased porosity, cracks and permeability. The physical state of the material was discussed as melting leads to convection and turbulent mixing, and the orientation of an item will greatly affect the response.

The formation of decomposition products and their location within a material/system needs to be understood; including the subsequent effect on swelling, ullage formation, and venting. The work highlighted the information required for constitutive models to describe the reactions.

Violence

Participants captured a current understanding of the factors influencing reaction violence with respect to force and area. A range of experimental techniques were described that are currently used to measure the initial stages of case expansion. The complexity of these techniques varied from optical methods to fast x-ray systems. It was noted that less techniques existed for determining pressurisation of the test item.

A number of gaps associated with data capture were highlighted, including measuring internal and external pressure, pressurisation response and collection, tracking and assessment of fragments.

Relating reaction violence back to system parameters was still seen as a step too far. No quantifiable metrics exist providing a confidence level in measuring reaction violence.

Chemistry & Material Parameters

Physical, chemical and mechanical properties required to model and understand cook off were defined. It was highlighted that macroscopic information, e.g. particle size, morphology, was also required to aid the modellers.

Material properties were well understood across mild temperatures but less so as temperatures approached cook off ignition temperatures. Information and experimental techniques exist to determine the effect of pressure on a material parameter, yet little information is actually available.

It was highlighted that gaps in knowledge exist for both ingredients and formulations at elevated temperature, pressure and specifically in damaged materials. Critical to modellers are reaction pathways and parameters which have only been derived for 2 – 3 materials. Ab initio experiments exist to fill this gap but are resource intensive.

The reporting of experimental errors and boundary conditions were highlighted as an immediate solution to improving fidelity to models.

Modelling

The modelling focus area discussed the currently available tools and their abilities and shortcomings. A typical point of discussion was the availability of tools, and the fidelity to which they are capable of resolving or predicting behaviour. It was highlighted that modelling is not one process, but an agglomeration of processes that can capture the many length and time-scale variant systems that are represented in typical cook off simulations.

One clear statement of the participants was that slow and fast cook off should not be viewed as separate processes requiring separate simulation tools or models – a well-posed model and/or simulation tool should be able to capture thermal behaviour, no matter the timescale, given the appropriate insight into material thermal damage evolution. This however was another of the critical gaps identified by the participants, as the thermal properties of materials at ambient and elevated temperatures, as well as the thermal damage evolution that occurs as materials transit through large temperature changes, are not characterized. This was also identified as a shortcoming in the experimental domain, as this type of information is just not available.

Pre-ignition simulations only use thermal behaviour, chemistry, and implicit mechanical information of pristine materials (which are assumed to be relevant throughout the heating process) and a gap exists in simulating mass transport. Ignition & post-ignition can be modelled through pressure and temperature measurements. Commercial codes lack a burn component and several models were identified to improve this area.

Chemistry & Materials Process

A review of previous presentations and focus area outputs led to an agreement on the tests that need to be performed to capture information for the modeller and fit within the hierarchy structure. It was identified whether a test could provide information at ambient, increased temperature, increased pressure and on damaged material. Many laboratories present had the capability and equipment to gather the physical and chemical properties of their energetic and non-energetic materials.

The gaps in testing echoed the need for a thermally damaged material test as a function of burning rate. It was acknowledged that high temperature performance tests, e.g. wedge test, were extremely difficult due to the effect of temperature on multiple parameters.

It was discussed that material properties are not gathered routinely despite the need for the information by the modelling community. The information should be gathered at the research level and could form part of an energetic materials requirement alongside hazard and performance information.

Scaled Testing

A number of new tests were described to account for differences in material and/or mechanism. It was concluded that there is not one small scale test that fits all, yet all scaled tests have similarities in design.

It was highlighted that heating conditions, convective air flow versus conductive heating, can influence the ignition location; characterisation and modelling of test set up is recommended.

Interpretation of reaction is currently limited to fragmentation of the vehicle and temperature of reaction. Yet a number of diagnostics are available to improve understanding, modelling and prediction.

Hierarchy

An agreement was reached on a hierarchical approach to develop understanding and assess munition response. The levels of testing were defined along with the information required from material properties, scaled testing and all up round results. It was highlighted that modelling needed to be coupled to all levels to allow correlation of behaviour and response between levels. Other points raised on modelling included:

- Recognition that currently, there is no validated model to predict reaction violence (which is not well defined).

- Agreement that modelling should be used to develop testing capabilities

Also recognised during the discussion, was that requirements with respect to confidence of assessment are not expressed in a meaningful way.

It was agreed that a case study was required to exercise the linkages between each level in the hierarchy. There was support for munition test information to be made available and a working group created to exercise the hierarchical approach.

Overall conclusions

Overall it was felt that the workshop was successful in bringing together the current SMEs on cook off and allowing discussions to take place. The output of each group will be recorded in further detail within several MSIAC reports.

Agreement was reached on current tests, models and parameters needed to assess cook off across the scales and that a number of new tests are available to elucidate mechanisms. Several areas were identified where further experimental information was required to aid modelling and simulation.

Damage, and its evolution, are key to understanding reaction. Violence of reaction still requires a better description.

The effect of heating rate on the response of energetic materials was shown to be driven by a number of factors including time, concentration of decomposition gases, evolution of ullage and physical and chemical changes to materials. At a system level there is complex interplay between dP/dt, Pmax and venting.

It was also concluded that work on the topic should continue through virtual space on the MSIAC ShareFile service. Reviews of the workshop reports by participants will take place during the summer. A full report on the workshop findings will be provided later in the year.

It leaves us to say that the success of a workshop can be measured by the degree of participation by its attendees. The attendees at the Science of Cook Off workshop were fully engaged and stayed on topic for the full five days to which we thank you all.

Dr Matthew Andrews, Dr Michael Sharp (PM), Emmanuel Schultz, Wade Babcock and the MSIAC team

PS. MSIAC produced a limited edition mug for the workshop which turned in to a very limited edition due an issue with delivery to the conference centre. These mugs have now arrived back in Brussels and we will do our best to get them to the attendees.

Figure 2 Rare Workshop Mug